Was ist das Besondere an Besonderen Merkmalen ?

A blog by Dr. Uwe-Klaus Jarosch, July 2025

It is always creates discussions : Special Characteristics

In many comodities Special Characteristics (SCs) are mandatorily requested.

But why and for when ?

There is an ongoing conflict between the developers who place the Special Characteristics on the drawing and those guys on the shopfloor who need to operate the SCs and will “suffer” them.

Ideally, SCs are ” as little as possible, as many as needed”.

In this blog I would like to give brief criteria to make “as much as needed” reasonable.

SCs are not intended to make the design safe.

SCs serve ONLY to have attention in the production process and to care for characteristics that otherwise would jeopardize follow up functionalities.

Examples:

The material in a drive shaft must withstand the most extreme accelerations and deceleration (recuperation) whithout damage or break. For this purpose the given geometry must have material properties on the outer 3mm with a minimum tensile strength, because main part of the loads will be transfered in this area.

If the material properties are not to the design spec a collaps of function for the drive shaft may happen.

3 sheet metal layers are positioned and clamped near to a weld seam by a threaded connection.

The weld seam is not relevant for the joining. But weld spatter may occur from the weld process. Weld spatter in the area of a threaded connection may have the effect to clamp by the pretention not in a given area but only via the spot of the spatter. The weld spatter will be flattend, the joining will relief and loose its pretention. In consequence the join can get loose. Therefore, major attention needs to be taken to keep the joining area free of weld spatter.

In both examples the product would either not be feasible to be properly produced or it could fail suddenly in use.

Both is not acceptable and must not happen.

The potential causes are well known.

A Special Characteristic is pointing to the cause of such an issue on the shop floor. The danger to get such an issue shall be drastically minimized.

Only to mark and classify this characteristic on the drawing or to place a sign in the shop floor will not have the effect.

The pain in production is created by the actions, by specific inspections and controls for such a Special Characteristic.

For this set of actions from my perspective and experience there is the same rule: As little as possible, as much as needed.

Firstly, I would like to come back to the question when Special Characteristics are needed.

When do we have all facts to say: this characteristic needs to be special?

We need to be clear about 2 conditions:

1) To talk about Special Characteristics needs to have dedicated specifications with clear limits.

The saying is: Do you leave the specification limits your product will no longer work safely.

May be, the problem arises before you can use the product. The characteristic out of spec prevents to produce a good product in the next process step.

2) We talk about cause-to-effect relations, about a clear relation between the characteristic and its resulting function. In worst case the function is no longer given when limits are exceeded.

Not every part, not every step or production needs to be affected. But a failure rate in the single digit % range may be a commercial killer to product and process if there is only small margin.

Vice versa, we may argue:

If we could exclude to create such a potential failure by this characteristic only or if the cause to effect relation is only an assumption but not approved then obviously we do not have a direct effect, not a clear cause-to-effect relation to classify the characteristic.

From an development engineering point of view I need to provide numbers, data and facts:

- What is the given limit for my characteristic ?

- If I use this given range what is the effect in the target function?

What is the range in the tolerance of the target function used by the characteristic influcence? - May the tolerance range of the characteristic cause the fuction to leave the given specification limits?

- And will this violation of the limits lead to a drop of the function?

Many limits are given in a way to be far from a functional stop. Such cases are called “robust design”. But if the violation of the limit does not have a consequence, why should the characteristic be classified as a SC? - A next question to the developer is: Are the characteristic and the target function correlated? Is there a clear relation like rising characteristic results in rising function or similar ? Or do you only observe a cloud of fluctuating results, may be due to other parameters with influcence ? May be, there is an indirect relation. Then no direct cause to effect relation is given. This should exclude a classification as well.

- For this analysis of data I clearly recommend to use dedicated limit values.

Such limits need to be set and agreed and they will help to properly decide.

There are 3 limits to identify a Mayor Influence:

- Using the full band of tolerances for the causing characteristic the resulting function will change. If the function is changing by more than 50% of its tolerance band it is a major influence.

- Varying the causing characteristic the function value comes near to a tipping point by less than 10% of the given tolerance range*.

- The function results are statistically correlated to the causing characteristic. The correlation coefficient is >= 0,7. **

Condition 1 or 2 ANDE condition 3 must be fulfilled.

* A function value is regarded a tipping point where the function becomes irreversable, e.g. when a material strength is exceeded by the loads or the center of gravity is shifting over the edge of a supporting surface and will fall.

** Here I would like to mention an important restriction: To have two sets of data with similar distribution or trend will give statistical correlation. This does not necessarily means to have a causal connection. Please have a look in the blog “Korrelation und Kausalität” of my colleague Dirk Jödicke.

A FMEA is a BRUTE FORCE method to make the product safe.

If not everything is analyzed carefully and in detail then you will have gaps resulting in blind spots of the result.

How severe the consequences of a blind spot will be in the use case can only be evaluated in the view back.

A FMEA including really everything does not exist.

Therefore, the function and failure analysis reasonably is a step by step decision where to allow gaps and blind spots.

To identify Special Characteristics by the FMEA logic we need a number of steps:

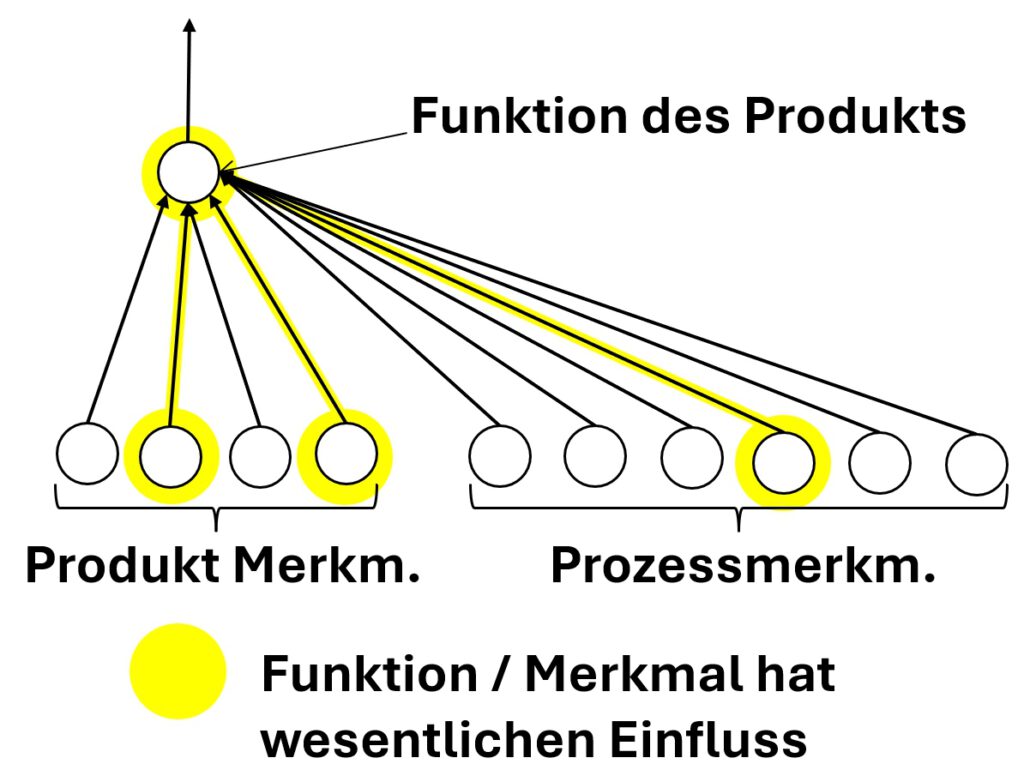

- Cause to effect relations have to be known or need to be investigated. The failure net will help a lot if physics is well transfered into the failure tree.

- In the net of cause to effect relations an effect may have several causes.

Here you must decide and make a difference which C t E relations, wich connections in the failure net of the FMEA are related to a major influence. Check the 3 conditions listed above (range of influence, near to tipping points, correlation). - In the failure net (what to use I strongly recommend) the severity S / Smax is visible.

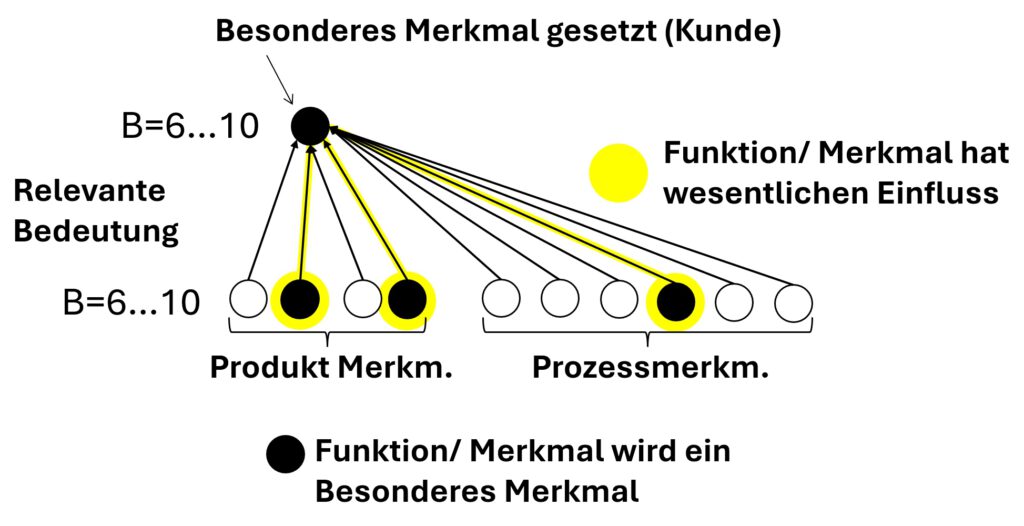

The severity S should be within a range with a lower limit and the type of special characteristic shall be dependent on the severity, e.g.:

S=6 -> for long time relevant for production -> HI, expensive

S=7,8 -> Main function of the procuet is jeopardized -> SC, BM-F

S=9 -> Conflict with law, public regulations, customer standards, homologation -> Legal, BM-Z

S=10 -> Danger for life and limb -> CC, BM-S, operational safety - The target function itself needs to be essential for the overall result. The target function shall have a major influence upwards in the failure net or the function should be classified as a special characteristic by the customer or the company from experience.

If we use the FMEA then we need to respect a further aspect and memory hook:

Special Characteristics are classifications of function, where characteristics are a specific subgroup of functions.

In the failure tree of the FMEA we get a much more detailed and more complete analysis than using the function tree. This is caused by the fact to potentially have several failure modes for a function or characteristic. Each of these failure modes may have several causes and several consequences. By this network we receive information from several consequences with their severity ratings as well as from the crutial points on cause level of the design or the process.

Therefore, it makes sense to check failure net links for a major influence. If at least 1 link is of major influence then the related function in the function net is as well.

Only this allows to do a meaningful analysis and SC classification.

Conclusion:

- With these few rules a complete logic is given to get a safe and reasonable classification of Special Characteristics.

- The idea to use filter for the phases of the development separately for design and process development becomes real and is rateable by physical relations.

- Using clear limits – as proposed – makes discussions short and decisions clear.

Limits may be aligned specifically for the company or product. Nevertheless, this way will guide away from meanings, assumptions and feelings to numbers, data and facts. - The FMEA is a brilliant template with technological knowledge included – if there is a description of the physics or chemestry of the product and the manufacturing process given.

- One question is not yet answered in this place: Which actions, which level of inspection, which capability requirement is needed for a given SC or CC?

Please have a look in here.

Stay curious.

Uwe Jarosch